Moonshine cube. How to make a still

Moonshine stills from copper began to be made quite a long time ago. Moreover, all parts without exception were made from this metal. According to connoisseurs of the true taste of alcohol, it is the copper surface that makes it possible to achieve a special taste of the drink, imbuing it with unusual shades. This is confirmed by French experts. The unit itself has a high level of strength.

Modern copper apparatus

The modification of such a device as a copper moonshine still has undergone some changes these days. The design is divided into separate components. It was called "alambik". Such units have an original design. They are often done with their own hands.

There are models that include a range of materials. For example, along with copper, stainless steel and glass are used. Quite often there is a device where only the tube and dome are made of metal.

Moonshine still made of copper, reviews of which are mostly positive, has the highest cost. Especially in comparison with economical options made from scrap materials with your own hands.

What drinks are produced from copper moonshine stills?

A copper moonshine still is designed for the production of wine, whiskey, Calvados and many other drinks of high category and quality. Often alcohol has a non-standard taste. Alcohol can come in different strengths.

Features of the copper fixture

What are distinctive features such a unit? Equipment for the production of alcohol differs not only appearance, but also by its technological and chemical processes occurring during the production of the drink.

A moonshine still made of copper has the following characteristics:

- High level of thermal conductivity. It affects the performance of the unit and the quality characteristics of the resulting product at the outlet. Since the steam cools better, the distillation speed also increases. The consumption of water volume and the content of related compounds are reduced.

- The device is characterized by reliable operation and strength. Copper practically does not wear out. The manufacturers themselves guarantee a long service life of the unit. If the device is assembled with your own hands, its durability may vary. It all depends on the level of skill of the manufacturer, the thickness of the metal used and some other indicators.

- Rust resistance.

- Conversion of aroma and purification of certain compounds. The taste in a copper device is more intense. Many experts talk about this. This can be explained by the fact that copper is capable of absorbing sulfur oxide, which emits very bad smell when making a drink such as mash. It may be noted that the metal dissolves some fatty acids.

- The infusion rate in copper is much higher.

- Copper units have a high level of safety.

- There are no other compounds mixed into the drink itself that disrupt its chemical composition and strength.

- There are no side effects observed during indoor operation.

What does a copper device look like?

It is not at all similar to similar devices made from a different material. They are usually made of stainless steel and tanks. The equipment has decorative elements. The device can be built with your own hands, have elegance and compactness.

Some foreign manufacturers produce similar units. They were called "alambics". The devices have a high level of performance. They are distinguished by different designs. The surface of such devices is carefully polished. Finished products can be purchased through online stores.

The price of exclusive devices is quite high. For example, in Portugal there are craftsmen who make devices using an ancient method. The metal is subject to careful selection, and soldering is done with silver.

As a rule, units of mixed configuration are used more often. They use a copper tube, and the main parts are made of stainless steel and special plastic.

There is an opinion that copper is not suitable for food purposes and, despite the reliability of this metal, it can be harmful to the human body. However, many companies produce devices made entirely of it, and statistics do not confirm the damage to health from it.

Self-production

Many people wonder how to make a moonshine still out of copper with their own hands. It is worth noting that it is better to purchase such a device ready-made. A person who is not endowed with special knowledge and experience is not able to assemble such a structure on his own. For those who still want to try making a moonshine still from copper with their own hands, there are a number of important recommendations.

Design

When manufacturing a unit, a project is required that will indicate what volume the device will have, and therefore what approximate level of performance. It is important to take into account all the cash costs associated with production. This is the purchase of copper sheets and auxiliary material with the presence of silver for soldering. You will need special tools for working with metal.

Drawing

It is not recommended to draw up a drawing of the device on your own, as this will require special skills. The device diagram exists in a ready-made version.

Pattern of parts

The thickness of the copper sheet is 1 mm. The outlines of future parts are applied to it. A cooling element for distilling alcohol should also be assembled. All parts are cut. This can be done using metal scissors or a circular saw. You should also prepare a pipe into which the cooler coil will be placed.

Processing parts and giving them a rounded shape

It is believed that working with copper requires experience, since the metal is difficult to shape. This stage requires working with tools such as a hammer, scissors and a mallet.

Soldering

This requires perseverance and accuracy. All parts should be assembled not only in a certain sequence, but also soldered correctly. The manufacturer does not always have silver-based soldering material. Lead is an analogue, but it does not have the proper strength. This is due to the characteristics of the metal, which can hardly withstand temperature changes and mechanical stress. The device can be polished to make it more attractive.

Making a copper coil

What should the coil of such a device as a moonshine still be made of? Does copper or stainless steel have higher functionality? The copper coil is superior in performance to similar devices. In addition, the fact that at high temperatures such a part will not react with alcohol is also taken into account.

Making a coil with your own hands

The coil is considered a very important part. To make it you will need a copper pipe, as well as a large pipe onto which it will be wound. This will give it shape. To prevent the shape of the pipe from being broken, it is filled with sand or another sealant. After this, you can start winding while maintaining the required distance. At the end of the process, the other end of the tube should be secured. After this, the pipe is freed from sand or other material.

It should be noted that the pipe with the coil will be located in the cooling pipe. Therefore, you should take into account its diameter in advance. After finishing work, the coil is placed in the refrigerator. Holes are made in it and plugs are placed. The surface is sealed to prevent liquid leakage.

Making a steamer

Moonshine stills made of copper with a steam chamber have a more complete design.

A steam steamer (reflux condenser or suction chamber) is not a mandatory component. The part is connected through tubes to the distillation cube and the coil. It serves to physically clean alcohol from harmful impurities.

The configuration of a homemade reflux condenser can be unified.

You will need:

- a three-liter jar with a metal lid that must close tightly;

- two fittings with external thread;

- two nuts;

- marker;

- heat resistant adhesive;

- awl.

Step-by-step instructions for making a steamer

- The diameters of the holes are drawn at the joints. The fittings are applied to the lid and outlined with a marker.

- Holes are made. An awl is moved along the drawn lines until the lid of the jar is rubbed through.

- The fittings are secured with nuts. In order to create high level To seal the holes, they are treated with glue.

- The steam chamber is hermetically connected to the coil and the cube.

Conclusion

Whether to make a moonshine still out of copper with your own hands or to purchase a ready-made copy is up to each person to decide for himself. Several decades ago, it was really better to assemble such a unit. For this purpose, pots, juice cookers, aluminum flasks and even glass cubes were used.

Today, for admirers of exclusive products, there are homemade moonshine stills made of copper, which are characterized by an original design.

Currently, alcohol production is undergoing significant changes. If previously ready-made devices made of copper were presented by foreign companies, today on the market you can find units of domestic production.

The buyer has the opportunity to choose models from a wide range. They vary in price, volume and performance level. A warranty card is provided for the finished product. You can also get necessary advice on the use and care of the device.

Somehow I missed this topic. I must say - completely undeserved. In principle, many will say that the design of the cube, as they say, “does not affect speed.” However, the design of the cube sometimes has a very significant impact on the ease of use. And in some processes (for example, when working with grain mash) it can also affect the overall speed of the process.

Let's look at the main variations of cubes, their strengths and weaknesses. Of course, I will not disassemble non-standard homemade products. Let's talk only about the most common options, built on standard components. The first in the row will rightfully be the well-deserved

Milk flask

(can, container from the milking machine). Perhaps the most affordable option as a basis for cube construction.  I myself have two pieces of 40 liters each, both bought used for 1000 rubles each (the price for them was quite stable before the crisis, for example, I bought mine several months apart, and I also “picked around” - I chose a cleaner one yes more equally). It is irrational to take a smaller volume, since the price differs only slightly, but the benefit of a larger one is much greater. It’s better to buy used ones, since most of them are old, Soviet-era vessels - I like them better. The new ones are somehow flimsier, thinner. Aluminum is perfectly processed; any necessary holes can be made with improvised means. The fittings used are standard brass or bronze (available at any plumbing store for a reasonable price). You can use original rubber gaskets under the lid, wrapping them with plumbing foam. If the gasket does not hold or is not there at all (a reason to negotiate the price - a new one costs from 50 to 400 rubles, depending on the greed of the sale), it does not matter either. On one of my flasks, the gasket, after working for several months, began to corrode and I replaced it with a piece of silicone hose (11 by 16 mm), joining it with a piece of silicone hose of a smaller diameter (8 by 10). Works great.

I myself have two pieces of 40 liters each, both bought used for 1000 rubles each (the price for them was quite stable before the crisis, for example, I bought mine several months apart, and I also “picked around” - I chose a cleaner one yes more equally). It is irrational to take a smaller volume, since the price differs only slightly, but the benefit of a larger one is much greater. It’s better to buy used ones, since most of them are old, Soviet-era vessels - I like them better. The new ones are somehow flimsier, thinner. Aluminum is perfectly processed; any necessary holes can be made with improvised means. The fittings used are standard brass or bronze (available at any plumbing store for a reasonable price). You can use original rubber gaskets under the lid, wrapping them with plumbing foam. If the gasket does not hold or is not there at all (a reason to negotiate the price - a new one costs from 50 to 400 rubles, depending on the greed of the sale), it does not matter either. On one of my flasks, the gasket, after working for several months, began to corrode and I replaced it with a piece of silicone hose (11 by 16 mm), joining it with a piece of silicone hose of a smaller diameter (8 by 10). Works great.

The disadvantages include:

1. Does not like alkaline environments. There is no need to wash with any “moles” or other alkaline-based products. Very rapid failure is ensured - the surface becomes ulcerated and holes form.

2. Doesn't like cold water. The result is the same as from the action of alkali, the process is just slower.

3. You have to fasten the connecting elements with threads and without welding, sooner or later they all begin to unscrew, and soldering aluminum is tricky (at least that’s how I learned it - the ease of assembly is fascinating and it’s easier to give up on future difficulties - “it’ll do just like that”, but periodically you have to tighten it up). For me this is perhaps the biggest drawback.

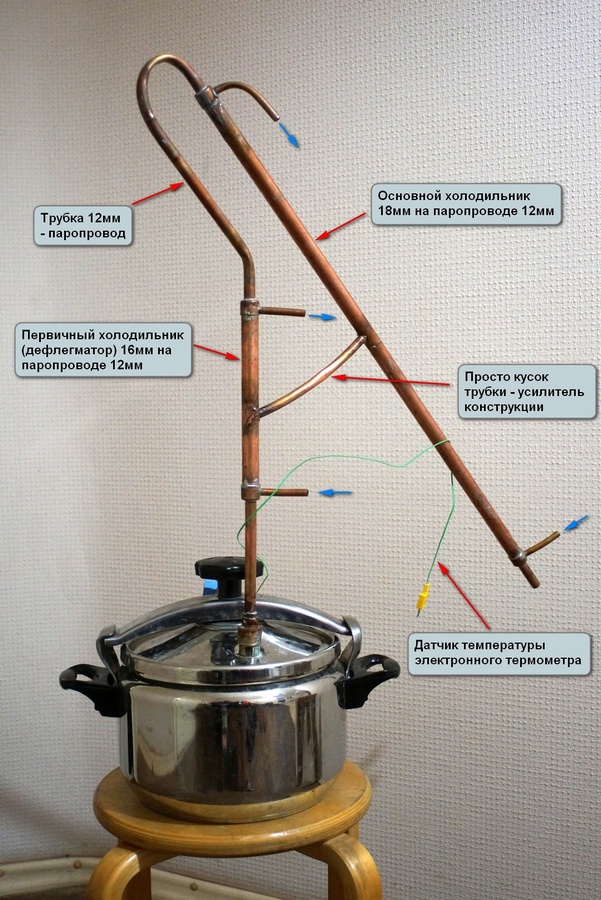

Pressure cooker. This version of the cube is good for everyone, except for one thing - the volume of pressure cookers is usually no more than 12 liters (usually 9-10 liters, or even 5-6). Because of this, it is not rational to put heating elements in a pressure cooker; you have to purchase an induction heater (increasing the price of an already not very profitable device due to the small volume) or heat it with gas (impossibility of insulation, which, however, is compensated by the small volume) and often encounter height restrictions ( does not pass under the hood, etc.). It is usually used as a “starting” cube for deciding whether to develop.  I use a 9L stainless steel OKA pressure cooker. I removed the standard valves from it, installed a 1/2″ adapter (on a thread with a nut and a Teflon gasket) in the hole of one of them, and a thermometer in the hole of the other. There are aluminum pressure cookers - they are easier to modify. I chose stainless steel because of its durability and ability to adapt to distillery needs without damaging it. At any time, you can remove the distiller and thermometer, replace the valves and use the pressure cooker for its intended purpose. Quite often I use it to make gin (less often absinthe and other drinks based on essential oils plants). This is much more convenient than driving a large cube.

I use a 9L stainless steel OKA pressure cooker. I removed the standard valves from it, installed a 1/2″ adapter (on a thread with a nut and a Teflon gasket) in the hole of one of them, and a thermometer in the hole of the other. There are aluminum pressure cookers - they are easier to modify. I chose stainless steel because of its durability and ability to adapt to distillery needs without damaging it. At any time, you can remove the distiller and thermometer, replace the valves and use the pressure cooker for its intended purpose. Quite often I use it to make gin (less often absinthe and other drinks based on essential oils plants). This is much more convenient than driving a large cube.

Cooking pots and kettles

. Of course, you need to purchase stainless steel pans to build a cube, but aluminum ones are now difficult to find, and enameled ones are not suitable. When choosing such a base, you need to pay attention to the thickness of the material and, especially, the rigidity of the lid - you will often place a very heavy device on it. If you are going to use induction, then pay attention to the material of the bottom (not all pans are suitable for use with induction cookers; this, by the way, is a general note for any cube).  The main problem when constructing pot cubes is sealing the lid. Sometimes you can find a gasket from some silicone baking mold or silicone mat (appeared in lately, you can buy it on ebay in the required size), sometimes you have to weld the lid and equip it with a welded flange (or even replace the lid with a suitable circle made of a 3mm thick sheet). In general, the “pan” option is not suitable for home cube construction due to the initial cost of the pan itself and the need for welding (good or bad soldering). And most importantly, due to the presence of a very strong alternative in the form

The main problem when constructing pot cubes is sealing the lid. Sometimes you can find a gasket from some silicone baking mold or silicone mat (appeared in lately, you can buy it on ebay in the required size), sometimes you have to weld the lid and equip it with a welded flange (or even replace the lid with a suitable circle made of a 3mm thick sheet). In general, the “pan” option is not suitable for home cube construction due to the initial cost of the pan itself and the need for welding (good or bad soldering). And most importantly, due to the presence of a very strong alternative in the form

Stainless steel beer keg

. Definitely a great capacity. Thick wall, stiffeners, convenient volume (20, 30 and 50 liters). It can be used without modification, installing the device on a standard 2″ neck mount (preferably with a three-clamp, then no welding or other methods are needed at all). Easily amenable to deep modification, after which you will get a truly convenient cube for all occasions. The illustration shows a cube from a 50 liter keg with a welded pressure cooker, resolving issues sealed neck. The disadvantages include the need for argon welding, or, at worst, hard soldering.

Stainless steel beer keg

. Definitely a great capacity. Thick wall, stiffeners, convenient volume (20, 30 and 50 liters). It can be used without modification, installing the device on a standard 2″ neck mount (preferably with a three-clamp, then no welding or other methods are needed at all). Easily amenable to deep modification, after which you will get a truly convenient cube for all occasions. The illustration shows a cube from a 50 liter keg with a welded pressure cooker, resolving issues sealed neck. The disadvantages include the need for argon welding, or, at worst, hard soldering.

I consider this to be the pinnacle of amateur cube building today. steam-water boiler (PVC)

.  Structurally, it consists of two nested containers. The inner container is actually the cube, and the outer one plays the role of a shirt for it. A certain amount of water is poured into the shirt, which is heated using heating elements. It turns out to be a kind of steam-water bath for the cube. This achieves good uniform heating of its entire surface with a very small temperature gradient at the boundary between the cube wall and stillage. No local overheating, burning, etc. In addition to heating, you can also cool the contents of the cube by running cold water through the jacket. This alternation of heating and cooling is necessary when preparing grain (starch) mash, where you must first heat for boiling, then cool for saccharification and then for the actual fermentation. It is also very convenient for brewing beer. Of course, such a version of the cube is, to put it mildly, inexpensive and you need to acquire it with a clear understanding of why you actually need all this.

Structurally, it consists of two nested containers. The inner container is actually the cube, and the outer one plays the role of a shirt for it. A certain amount of water is poured into the shirt, which is heated using heating elements. It turns out to be a kind of steam-water bath for the cube. This achieves good uniform heating of its entire surface with a very small temperature gradient at the boundary between the cube wall and stillage. No local overheating, burning, etc. In addition to heating, you can also cool the contents of the cube by running cold water through the jacket. This alternation of heating and cooling is necessary when preparing grain (starch) mash, where you must first heat for boiling, then cool for saccharification and then for the actual fermentation. It is also very convenient for brewing beer. Of course, such a version of the cube is, to put it mildly, inexpensive and you need to acquire it with a clear understanding of why you actually need all this.

Recently, stainless torque converters have been used as the basis for the cube, but I don’t particularly like this option. They are not cheap and require as much work as a keg. In addition, containers with a volume of less than 80 liters have a horizontal orientation and a hatch at the end. It turns out not very convenient to work with.

Resume. At the very beginning of distillery activity, you should not purchase an expensive still or bother with self-production complex container. It is still unknown how much you will really need all this later. It makes sense to get a milk flask or even a pressure cooker. It won’t be a shame to throw out the first one, but the second one will come in handy even if you have advanced cubes. In any case, remember - the cube is just part of your distillation system and its volume must be combined with the volume of the fermentation tank, the amount of finished product you desire and other indicators. It’s quite funny, for example, to try to fill a 35-liter barrel with distillate using a pressure cooker as a distillation cube. 🙂

When acquiring a cube, pay attention to the following points: the possibility of insulation (if it is without insulation), the presence of a wide neck to ensure convenient maintenance and the possibility of subsequent modification (often you don’t know today what you want tomorrow), the presence of the necessary connecting elements (pipes), sufficient overall structural strength.

First you need to decide on the subject of consideration. So, a distillation cube is a sealed container designed for heating and subsequent distillation of mash or initial wort. Speaking in simple language, this is a reservoir in which the initial separation of the mash into fractions occurs, namely, alcohol-containing vapors are released, which are sent further into the system.

It is quite possible to make a distillation cube with your own hands, but for this you need to have a number of skills and knowledge general principles process. So, in order to make such a container, you need to fulfill several requirements:

- The tank lid must be sealed. Even slight air etching will negatively affect both the efficiency of the evaporation process and the quality characteristics of the resulting distillate.

- Alembic moonshine still must have a volume suitable for a certain amount of initial liquid, as well as sufficient for the evaporation process to occur. If this parameter is selected incorrectly, boiling mash will splash out into the outlet tubes, which is extremely undesirable.

- It is necessary to have one or more holes equipped with special fittings.

- The material from which the distillation cube will be made with your own hands should have as little chemical activity as possible, that is, not enter into chemical reaction with mash components.

Aluminum can is the most popular cube container, but not the safest

The main problem when doing work with your own hands will be ensuring tightness. As you can often see, the distillation cube of an old moonshine still was made from an ordinary milk flask. In general, this option is quite functional, but careful modification of the lid is necessary, since the standard option did not provide for the formation of internal pressure.

Among other things, the tank can be equipped with a built-in heating element, which will act as a heating element and ensure the operation of the system.

Types of stills

Based on the materials used in manufacturing and some structural differences, the distillation cube can be of several types.

- Aluminum flask. This option is distinguished by its large volume, accessibility and ease of operation, and almost every person with basic skills in handling the tool can do it with their own hands. However, such a tank is quite bulky, unaesthetic, and aluminum oxidizes over time, which leads to a decrease in the quality of the resulting product. It is also worth considering that a system equipped with a flask container will not function if an induction cooker is used.

- Pressure cooker. You can make a reservoir for evaporating mash with your own hands from a household pressure cooker. Among the advantages are ease of use, functionality and compactness, but such a capacity will have modest performance.

- Beer keg. Beer kegs can be used to make a distillation vessel. These barrels are made of stainless steel and are sealed. You can select the required volume, and with some modifications, equip such a tank with the necessary sensors, for example, a thermometer. You can do all the work yourself, which means you can save money. A still from a beer keg is the most preferred option for making a moonshine still.

- Ready-made tanks. To make a distillation cube for a moonshine still, you can purchase ready-made containers produced at the factory. Such a product will have all the necessary properties, but its use will require financial investments.

- Pot. The simplest tank for distilling mash can be made from an ordinary enamel pan. You will need to make a special gasket with your own hands to ensure tightness, and also equip a locking system.

You can install the heating element yourself

Among other things, the elements of the moonshine still under consideration may differ in the method of heating the mash. So we can distinguish between externally heated containers and tanks equipped with a built-in heating element. A distillation cube with a heating element is quite convenient and does not require the use of external heating devices. The use of such a device is possible in any place where there is an electrical outlet, which makes it an ideal country option.

Operating principle of a distillation cube

- The present mash is poured into the container, after which the lid is sealed.

- Next, the liquid is heated. This can be either with the help of external heating devices or with the use of built-in elements, if it is a distillation cube with a heating element. It is important to consider here that the primary evaporation of alcohol-containing vapor begins to occur already at a temperature of about 80 degrees Celsius. To increase the efficiency of the process, additional insulation of the container can be carried out.

- The mash is brought to a boil, while inside the container it forms high blood pressure, causing the pairs to move further through the system.

Secondary separation of steam into fractions is carried out in a steam tank and a bubbler, if they are provided for in the design. It is not appropriate to talk about how within the framework of this article, but information can be obtained from other materials.

How to make a still

To fully understand the issue, it is necessary to consider the process of making a distillation cube from a beer keg and a saucepan, as the most common options.

Cube from a pan

If the tank for distilling mash is planned to be made from a saucepan, then the actions will be carried out in several stages:

- First you need to purchase a container of suitable volume. As mentioned above, this parameter should be selected based on the expected volumes of raw materials and the free volume that must remain to ensure vaporization.

- Next, at some distance from the neck, special locking devices are fixed that will hold and seal the lid. You can fasten the latches using any available method (welding, rivets), the main thing is to ensure the tightness of the connection.

- It is necessary to drill holes in the lid and screw into them special fittings necessary for attaching the thermometer and pressure gauge.

- At some distance from the bottom of the pan, a hole is drilled, the diameter of which must correspond to the fitting installed for draining the stillage.

The main issue that you should pay attention to when assembling such a distillation tank is ensuring its tightness. For these purposes, previously, ordinary dough was often used, but now it is more expedient and convenient to use special silicone gaskets and sealants.

Distillation cube from a beer keg

You can also make a distillation container from an ordinary beer keg. To do this, purchase a barrel of the required volume. Next, a hole is drilled in the lid to install the thermometer. A thread is cut in the hole, and the same is cut on the tube that will be screwed into it. Thus, a fitting is formed that will allow convenient installation and removal of the sensor.

At some distance from the bottom of the keg or in its bottom, a hole is drilled to drain the stillage, into which a special fitting will be installed. The tank lid already has a technological hole that will be used to connect the tubes through which alcohol-containing steam will be supplied further through the system.

To simplify the process of heating the mash inside the distillation cube, the tank can be additionally insulated from the outside. For these purposes, for example, foil material intended for vapor barrier of premises can be used.

There are quite a lot of ways to make a distillation cube for a moonshine still. If you have certain experience and tools, you can carry out the work yourself. Choose the most for yourself suitable option everyone can.

The basis of the distillation system is the still cube. The volume of processed raw materials depends on the distillation container, the material and its coating from which it is composed, which is directly reflected in the results of distillation and the volume of the finished alcoholic product. Buying a ready-made cube or container for a moonshine still is not a cheap pleasure. It will be easier and more economical to make it yourself.

Operating principle of a distillation cube

Before you begin assembling a distillation system or start creating a container, it is advisable to understand the functions of the cube itself and its role in the final form of the apparatus. Most often, experienced moonshiners install cubes on their systems, the top of which looks like a dome. As for the capacitive volume, everything here depends entirely on your personal needs and capabilities. Typically, the volume is selected so that the cube contains at least 5 kilograms of raw materials, and metal is used as the material from which the container itself consists.

The lid or upper part of the container must be equipped with a special device through which steam will then escape. When the raw material boils, steam will rise up and enter the refrigerator. After the steam will condense, turning into natural alcohol. The spent mash remaining in the distillation tank is then removed through a special valve located under the still.

Many owners of moonshine stills consider it advisable to buy ready-made distillation containers, which is due to the exceptional importance of this part in the finished unit. These usually last longer, but are also more expensive. Stainless steel is considered the most reliable material for such a cube. The rest of the moonshiners, who are not against their own “adjustments”, experiments and optimization of the distillation system, prefer to make cubes for moonshine stills with their own hands. All you need to make your own container is to purchase necessary materials and be able to operate a soldering iron.

How to choose the right material for a distillation cube?

Various dishes and containers can serve as a container for distillation. Its durability and effectiveness will directly depend on the experience, knowledge and skills of the inventor or manufacturer.

It is important to understand that the quality of an alcoholic drink lies not only in its strength, but also directly depends on the presence of certain flavors that may appear during the process of obtaining the drink. No matter how many experiments are carried out, one thing is clear: there is no need to reinvent the wheel. Stainless steel is best suited to achieve maximum quality of the original product. It withstands long-term loads well high temperature and does not enter into all sorts of reactions with some products that may be contained in the mash. In stainless steel stills for moonshine stills, the appearance of harmful and unfavorable substances for the body is excluded, which cannot be said about aluminum containers.

DIY steel container

There are several options for creating a moonshine unit with your own hands. The most difficult thing will be the use of stainless steel sheets, which after several difficult steps will turn into a ready-made container for distillation. Such an assembly takes place in several stages:

- First you need to select the appropriate steel. First of all, you should pay attention to its thickness. 0.5 mm. would be an ideal option; thicker sheets will face the problem of “inflexibility” without special equipment;

- Now we cut out all the capacitive elements. First of all, it is necessary to carry out all the calculations on which the size of the cube will depend. Then transfer all theoretical measurements to the metal. Do not forget to take into account the features of the cube and design a valve for the removal of waste raw materials. Cutting should be done with a grinder or metal scissors. Difficulties may arise for those who are doing this kind of work for the first time. In other cases, the work is quite simple;

- Welding. Most often, it is safer to use soldering yourself, but if the steel is too thick or you have experience working with a welding machine, then it will be more practical to use this type of connection. Tin is perfect for solder. If you have never practiced this, then you first need to familiarize yourself with the technology for carrying out the work;

- Lid. The easiest option is to use a pressure cooker lid. All that remains is to resolve issues with its tightness and size. To avoid unnecessary costs and work, it is better to adjust the diameter of the container to the existing lid at the measurement stage;

- Fastenings for sealing the lid. Best option- construct similar to the closure of a flask. Additional materials will be required. Everything must be made of stainless steel;

- Install the temperature sensor.

The entire assembly, when studied theoretically, seems quite simple, but in reality it takes a lot of time and requires certain skills. It is not uncommon to find professionals who specialize in making steel containers. But this will, again, cost a pretty penny.

It is very important to carry out calculations as accurately as possible. The volume and extra costs and costs of purchased material will depend on them. When constructing small stills, the distillation process can slow down significantly.

Other methods for constructing stills

To prepare small volumes of alcohol, there is the option of using a simple pressure cooker with the largest possible capacity. By unscrewing the drain valve, you can make a transition to supply steam to the refrigerator. In this case, there is no need to worry about tightness; it is initially provided for in the manufacture of this kind of cookware. But even with a decent pressure cooker you won’t get a volumetric yield of finished alcohol. One alternative is to use a flask. The flask should be selected so that it does not contain aluminum.

Sophisticated moonshiners use stainless steel pans for distillation, which are subject to preliminary modifications. Simply put, they are rebuilt in the manner of pressure cookers: they ensure proper tightness of the lid and supplement it with a hole for steam outlet.

There are a myriad of homemade designs and adaptations for the production of moonshine stills, but not everyone will be able to replicate them with their own hands. In this case, it will be more practical and economical to purchase ready-made versions of the moonshine system, developed by specialists in this field. Sometimes the savings can be very conditional or affect the quality of the final product.

Don't forget that assembling the still or distillation container is only half the battle. The final version of the entire moonshine system should include coolers, steamers, thermometers, many connecting elements and additional elements necessary for the production of not only moonshine, but also other strong drinks. By studying such a complex science as moonshine, someday you will be able to make your own cognac, whiskey, gin and other popular alcoholic drinks.

The element is made exclusively of metal and can be of different volumes. In the upper part or lid, often in the form of a dome, a special steam outlet is installed. When the solution boils, alcohol-containing vapors rise and flow through the adapter into the refrigerator, where they condense into an alcoholic product. Almost every day, a valve is provided to ensure the release of the remnants of used mash.

For those who do not like experiments, they appreciate high quality and your time, it is better to give preference to a ready-made product. The distillation cube and accompanying paraphernalia can be purchased in a specialized store, including on the Internet resource.

The use of a stainless steel moonshine still is considered especially valuable, which affects not only the average cost of such equipment, but also its practicality and fairly long service life.

What can a distillation cube be made from?

Various dishes, containers and durations are adapted to the distillation container, and its functionality depends on the knowledge of the inventor and the skills of the manufacturer.

Most often, steel products are used for this, either made by hand or purchased ready-made. It is steel that is highly resistant to long-term temperature loads and does not react with chemical compounds contained in the mash. For high-quality alcoholic drinks, not only strength is important, but also the absence of extraneous flavors, and using steel surfaces, this can be achieved quite realistically. The ingress of compounds harmful to the body when using steel is also excluded, which cannot be stated with certainty for aluminum tanks.

Steel cube and is it possible to make it yourself?

If you decide to make a device for making alcohol with your own hands, then you can use several options for this. One of the most difficult is the use of stainless steel sheets, which, after quite complex manipulations, are transformed into a cube for distillation. The process looks like this step by step:

- Choosing the right steel, which involves selecting sheets of the required thickness, for example, 05 mm. If you take it thicker, then it will be impossible to bend it without special equipment;

- Cutting out and cutting out elements for the cube. Naturally, you first need to calculate the required dimensions of the container, reflect this on the pattern, and only then transfer it to the metal. Be sure to take into account all the nuances of the cube and provide a tap for removing the remaining solution. Metal should be cut using a grinder or metal scissors. At first glance, this activity seems simple, but if a person has not previously engaged in such work, then he may have difficulties;

- Welding or soldering. Basically, it is better to solder with your own hands, but if you have the skills to operate a welding machine and the thickness of the steel does not allow soldering, then you will need to use this type of work. Tin can be used as solder, and phosphoric acid can also be used. If you have no experience in such processes, then you should definitely study the technology;

- Selection of cover. For a moonshine still, you can use a lid from a pressure cooker; another question is how to make it airtight and select the right size. There are several options - initially calculate the diameter of the cube so that the existing lid will fit, or vice versa, which will require additional material costs, so you will have to separately purchase a pressure cooker of the required size;

- Installation of fasteners for subsequent sealing of the lid. It can be done by analogy with closing a flask. This may take some time, and you will also need auxiliary devices, including those made of steel. All elements must be made of stainless steel;

- Installing a temperature sensor.

This whole process seems simple only upon superficial study, but in fact, making a moonshine still with your own hands, in particular, a steel distillation cube, is only possible for real professionals. In order not to waste time, as well as to avoid accidents during distillation, damage to the product or poor quality, it is better to purchase ready-made equipment.

Sometimes you can find specialists who specialize in the manufacture of steel cubes, but then the guarantee of the moonshine still will also be questionable. You can only trust such a task to real professionals; it is better if they are trusted people, since the pleasure of producing a container for home brewing from stainless steel is relatively expensive.

In addition to following the technology for producing a metal product, it is important to correctly carry out the calculations. They are needed not only to determine the amount of material needed and plan material costs, but in order not to miscalculate the volumes. With a compact distillation cube, there will be the lowest productivity, which will significantly prolong the preparation of alcoholic beverages.

Purchasing a device made by professionals helps to facilitate the process of moonshine brewing, since the kit already contains everything necessary to carry out distillation and control it.

Other ways to invent a still

If you plan to produce alcohol in small quantities, then you can simply use a pressure cooker, choosing a product with the maximum volume. If you unscrew the drain valve, you can install an adapter to supply steam to the refrigerator. The tightness of the lid is ensured initially, as this is provided for by the manufacturing technology of such utensils. It is quite difficult to get a good product yield with a regular pressure cooker, so one of the alternatives is flasks, but not those that contain aluminum. This metal has long been no longer recommended for producing alcohol, although several decades ago it was especially popular.

A steel keg, similar to those used for transporting beer, can be used as a still. Such containers are quite difficult to obtain and mostly only directly from the manufacturer and it is not a fact that he has a retail outlet.

Some craftsmen adapt ordinary stainless steel pans for distillation, which are first subjected to partial modification. In other words, they make almost the same pressure cookers. Holes are made in the lids to allow steam to escape; the lid is supplemented with a special fastener to ensure tightness during the distillation process. Since pots can be of different sizes, containers can also be selected according to volumetric requirements.

Despite the numerous inventions of people trying to reduce the cost of producing a moonshine still without sacrificing quality, not everyone is able to do this with their own hands. In order not to take risks and actually get an alcoholic product with the desired strength, pleasant aroma and planned yield, you need to choose systems developed by professionals. Conditional savings or a desire to experiment can negatively affect the level of alcohol production.

Not everyone can make a sealed, easy-to-use distillation cube made of stainless steel with their own hands, but everyone can choose the best option in terms of cost and functionality. There are companies that organize the delivery of all the necessary attributes. The kit already includes a container for distillation, a cooler, a steamer, a thermometer, connecting elements and everything you need to make not only moonshine, but also cognac, whiskey and any other drink.